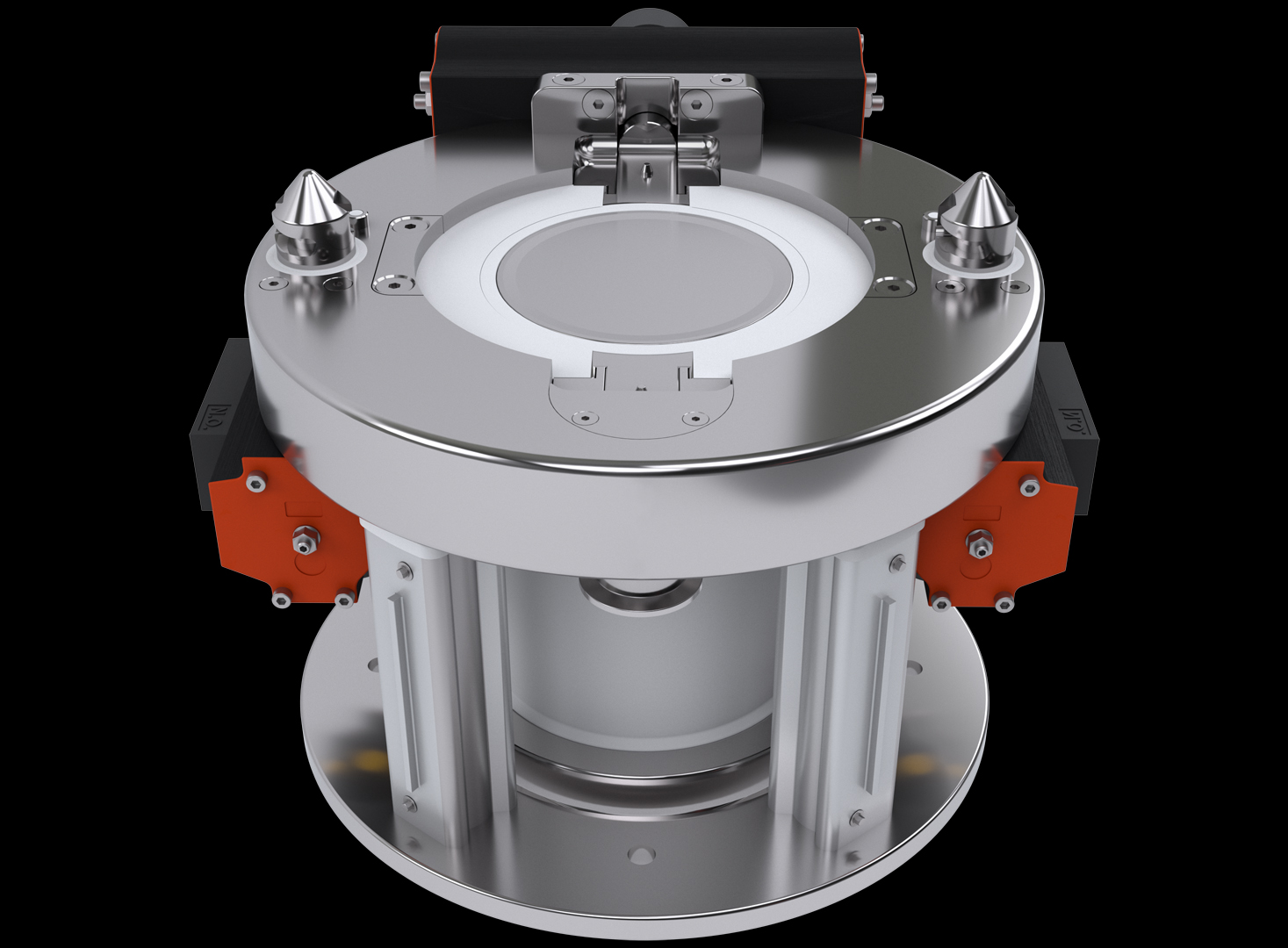

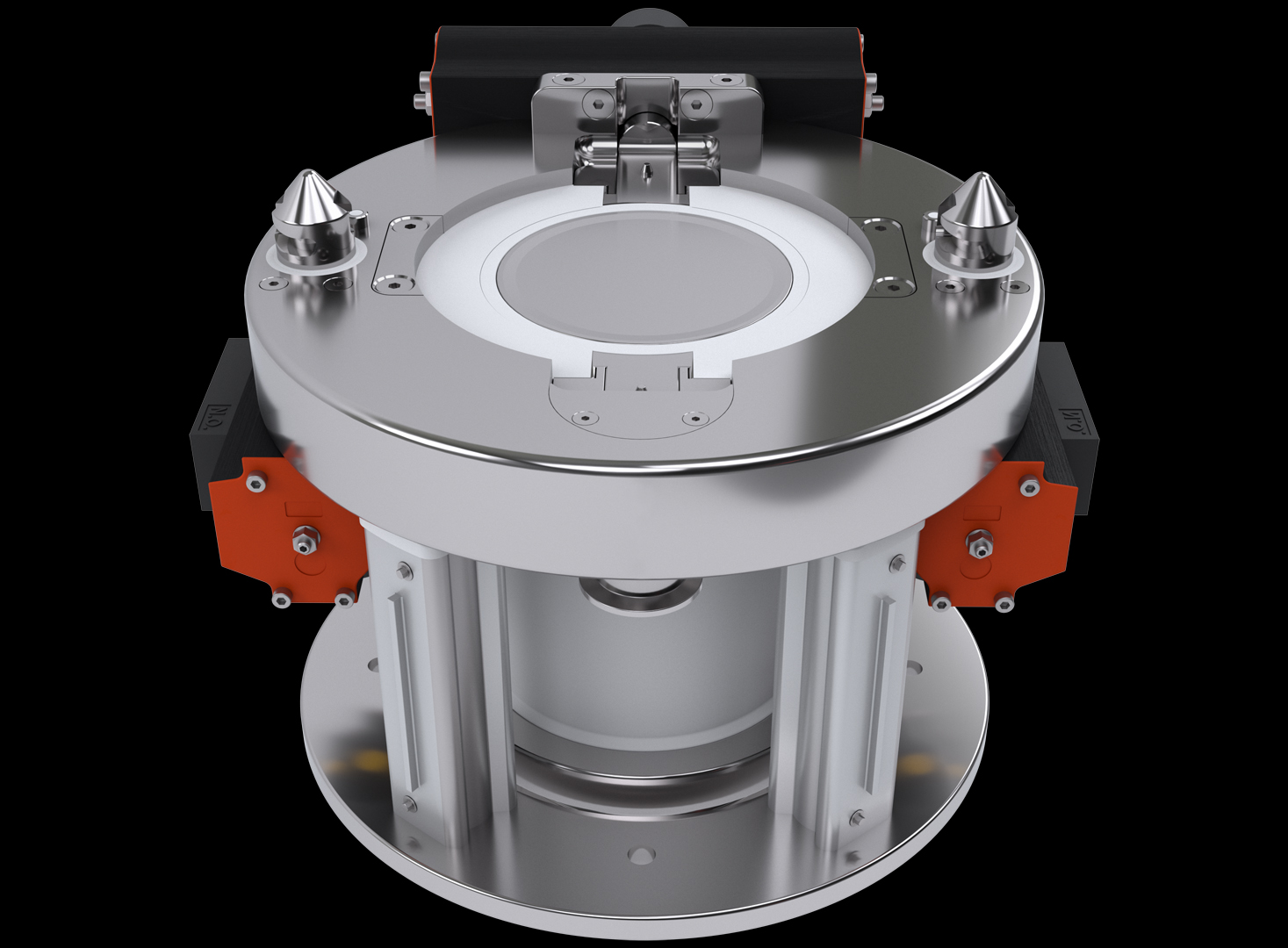

ASBV AM

Active Manual

Active valve with hand lever for manual operation.

Hazards are our core competence, because we deal with interfaces for the handling of highly active ingredients and toxic media on a daily basis. When asked which multi-use ASBV split butterfly valve system can be handled more flexibly than classic models, we have the fitting answer – in the truest sense: Our ASBV Split butterfly valve system. This technology is not only highly secure. For many years, it has also stood out for its robust design and large docking tolerances of up to +/- 14 mm. The floating active flange makes this possible. Intuitive and simple handling in the process makes the ASBV perfect.

Thanks to our ASBV split butterfly valve and the joint opening of active and passive valves, there is absolute certainty that product and environment never come into contact with each other. Contamination values of less than 1μg/m3 speak in favour of our ASBV split butterfly valve system and its technology, which has been thought through down to the smallest detail. Or, to put it simply: Contained powder handling at its best!

| Product | ASBV AM | ASBV AF | ASBV AE | ASBV AZ |

| Nominal sizes | DN 050 - DN 200 | DN 100 - DN 300 | DN 100 - DN 300 | DN 100 - DN 300 |

| Containment performance | < 1.0 μg/m³ | < 1.0 μg/m³ | < 1.0 μg/m³ | < 1.0 μg/m³ |

| Operation | manual | manual / automatic | manual / automatic | automatic |

| Process interface | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange |

| Material in contact with product (standard) | 1.4404 / 316L | 1.4404 / 316L | 1.4404 / 316L | 1.4404 / 316L |

| Material not in contact with product (standard) | 1.4301 / 304 | 1.4301 / 304 | 1.4301 / 304 | 1.4301 / 304 |

| Elastomers | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) |

| Bellows connection | - | - | Screwed to base plate / continuous | Screwed to base plate / continuous |

| Cleaning | WIP / CIP | WIP / CIP | WIP / CIP | WIP / CIP |

| Product | ASBV AM | ASBV AF | ASBV AE | ASBV AZ |

| Nominal sizes | DN 050 – DN 200 | DN 100 – DN 300 | DN 100 – DN 300 | DN 100 – DN 300 |

| Containment performance | < 1.0 μg/m³ | < 1.0 μg/m³ | < 1.0 μg/m³ | < 1.0 μg/m³ |

| Operation | manual | manual / automatic | manual / automatic | automatic |

| Process interface | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange | Tri-Clamp / screw-on flange / weld-on flange |

| Material in contact with product (standard) | 1.4404 / 316L | 1.4404 / 316L | 1.4404 / 316L | 1.4404 / 316L |

| Material not in contact with product (standard) | 1.4301 / 304 | 1.4301 / 304 | 1.4301 / 304 | 1.4301 / 304 |

| Elastomers | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) | EPDM / PTFE / FPM (each in white or black) |

| Bellows connection | – | – | Screwed to base plate / continuous | Screwed to base plate / continuous |

| Cleaning | WIP / CIP | WIP / CIP | WIP / CIP | WIP / CIP |

Every news about the company and

information about new products easily via e-mail

Contact

Every news about the company and

information about new products easily via e-mail

Contact

Single-Use

Multi-Use

Ball Segment

Andocksysteme G. Untch GmbH

Schweighofstr. 3

D-79410 Badenweiler

info@andocksysteme.de

+49 7632 823 82 0